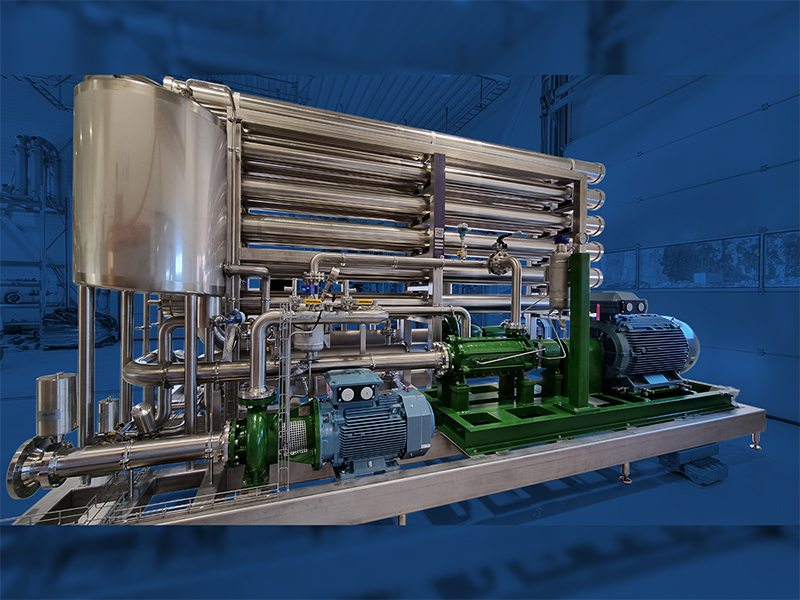

The combination of innovative membrane filtration technology and robust Dickow centrifugal pumps revolutionizes industrial filtration processes.

News

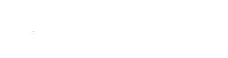

Heat transition with concentrated solar thermal

Article in VDMA magazine “Pumps and Compressors for the World Market […]” on concentrated solar thermal and innovative pumps by Dickow

In the modern industrial landscape, the heat transition is at the core of sustainability efforts. Dickow Pumpen from Waldkraiburg demonstrates how innovative pump technology can drive energy efficiency and resource conservation with its latest development. The magnetically coupled and self-venting pump, specifically designed for heat transfer applications, sets new benchmarks in pump technology.

Efficiency and Robustness in Action Tested by the German Aerospace Center (DLR), the pump handles temperatures up to 500°C and pressures of 50 bar in continuous operation without external cooling. This capability is based on the latest advancements in magnet and material technology, previously considered unattainable. The pump features self-degassing capabilities and requires no external cooling, making it an indispensable tool in demanding applications.

Sustainable Solutions for the Future The integration of thermal heat stores in concentrated solar thermal systems enables efficient use of solar energy to generate high temperatures. This technology not only provides direct heat but also stores excess energy, enhancing supply security and adaptability to energy demands.

Minimal Maintenance, Maximum Performance Dickow Pumpen's pump type NMX stands for high efficiency with minimal maintenance requirements. An oil change of the pump drive every 20,000 operating hours is the only maintenance needed, as the internal components are wear-free. This significantly reduces operational costs, making the pumps the ideal solution for users focused on longevity and minimal downtime.

With this groundbreaking technology, Dickow Pumpen underscores its leading position in the pump industry and contributes to a successful heat transition.

by Alexander Hammer

Industrial heat supply is responsible for a significant part of greenhouse gas emissions. But the days of fossil sources of energy are counted. Companies are recognizing more and more that they have a responsibility to the environment and at the same time can seize opportunities to remain competitive. Innovative technologies, alternative energy sources and new business models are ready. How can we make the transition from traditional heating methods to sustainable solutions? The heat transition in industry is more than just a technical changeover. This is the key to a sustainable, resource- efficient and future-proof economy.

Magnetically coupled works effortlessly with operating temperatures up to 500° C. source: DLR

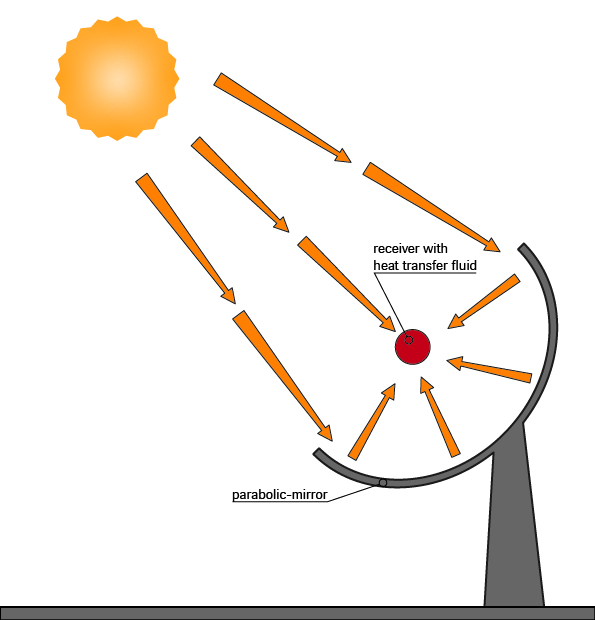

Concentrated Solar Thermal (CST) is a key technology that uses mirrors to bundle sunlight in order to generate heat. Although the use of solar power is not a revolutionary new concept, CST differs from photovoltaic systems in providing heat directly instead of electrical energy. This particularly leads to a significant increase in the overall efficiency of the system when generating heat. There are two types of systems that are suitable for CST: parabolic trough- and linear Fresnel-constructions. Both types of systems consist of oblong, concave curved mirrors (parabolic troughs) or flat, narrow mirrors (Fresnel). They bundle the sunlight and effectively focus the solar radiation onto a receiver pipe that extends along a focal line. A heat transfer fluid that circulates through this pipe absorbs the concentrated heat and transfers it to a heat exchanger or directly to a consumer.

source: Dickow Pumpen

Gamechanger thermal heat store

The integration of thermal heat stores in concentrated solar thermal systems is a real game changer and opens up new possibilities for a sustainable supply of heating energy. By efficiently using solar energy to generate high temperatures, these systems can not only provide heat directly, but also store excess energy. Thermal energy storage systems enable the heat generated to release at a later date, which is particularly important at times when there is little or no solar radiation. This flexibility increases the security of supplies and enables better adaptation to energy requirements, particularly in industry and the building section. This not only makes the use of concentrated solar thermal more efficient, but also embeds it more consequently in an integrated energy system that supports the transition to a sustainable, renewable energy future.

The pump: live-giver for constructions and systems

Pumps are essential in almost all industrial processes and act as the heart of these systems. Without them, today's standard of living would be almost unimaginable. From the industrial revolution through to the modern transition to sustainable climate neutrality - the use of pumps is crucial for the progress and efficiency of energy supply. They ensure, for example, that the retained heat arrives where it is needed, and are driving the transformation towards an emission-free future. Amidst of these rapid developments in pump technology, Dickow Pumpen from Waldkraiburg is contributing their 115 years of know-how. Due to the intensive research and development activities of the company based in Waldkraiburg, they are able to offer solutions that meet the challenges of today's industrial processes.

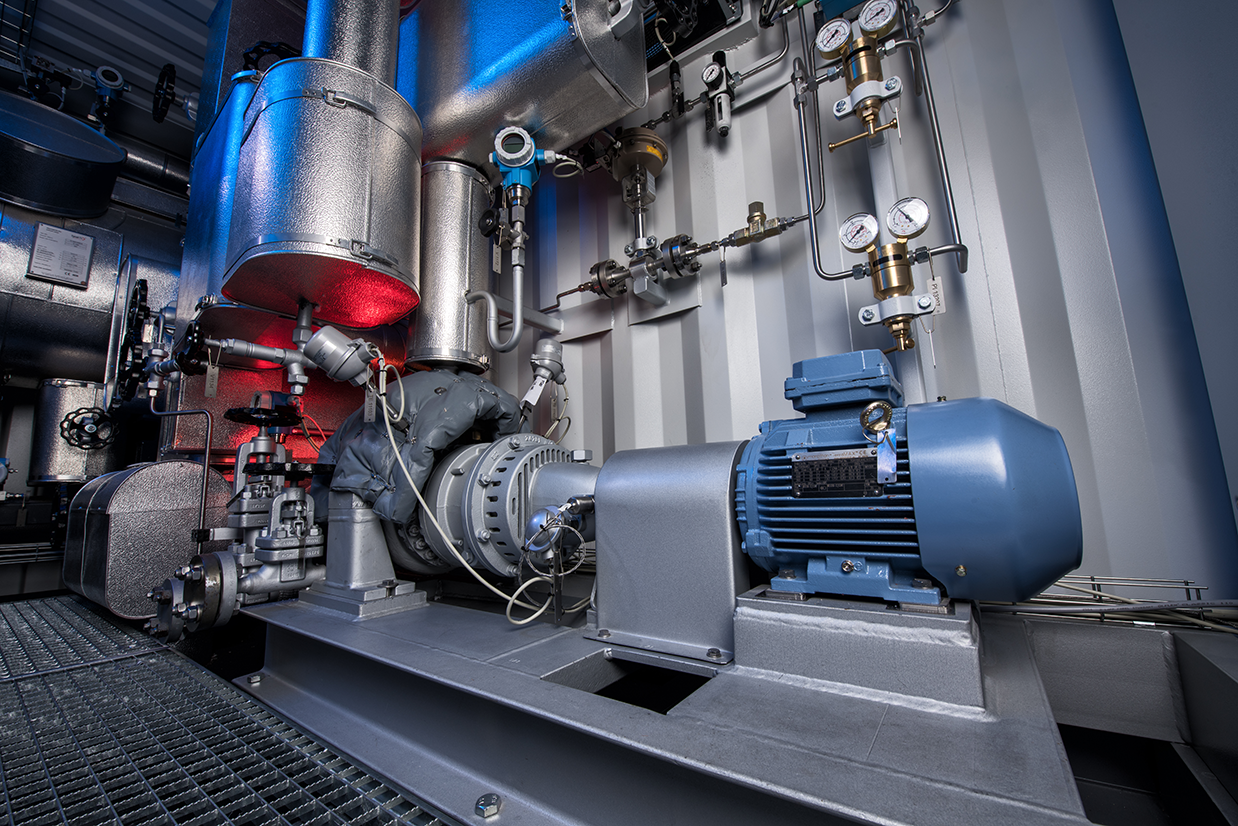

source: Dickow Pumpen

Efficient and robust in demanding applications

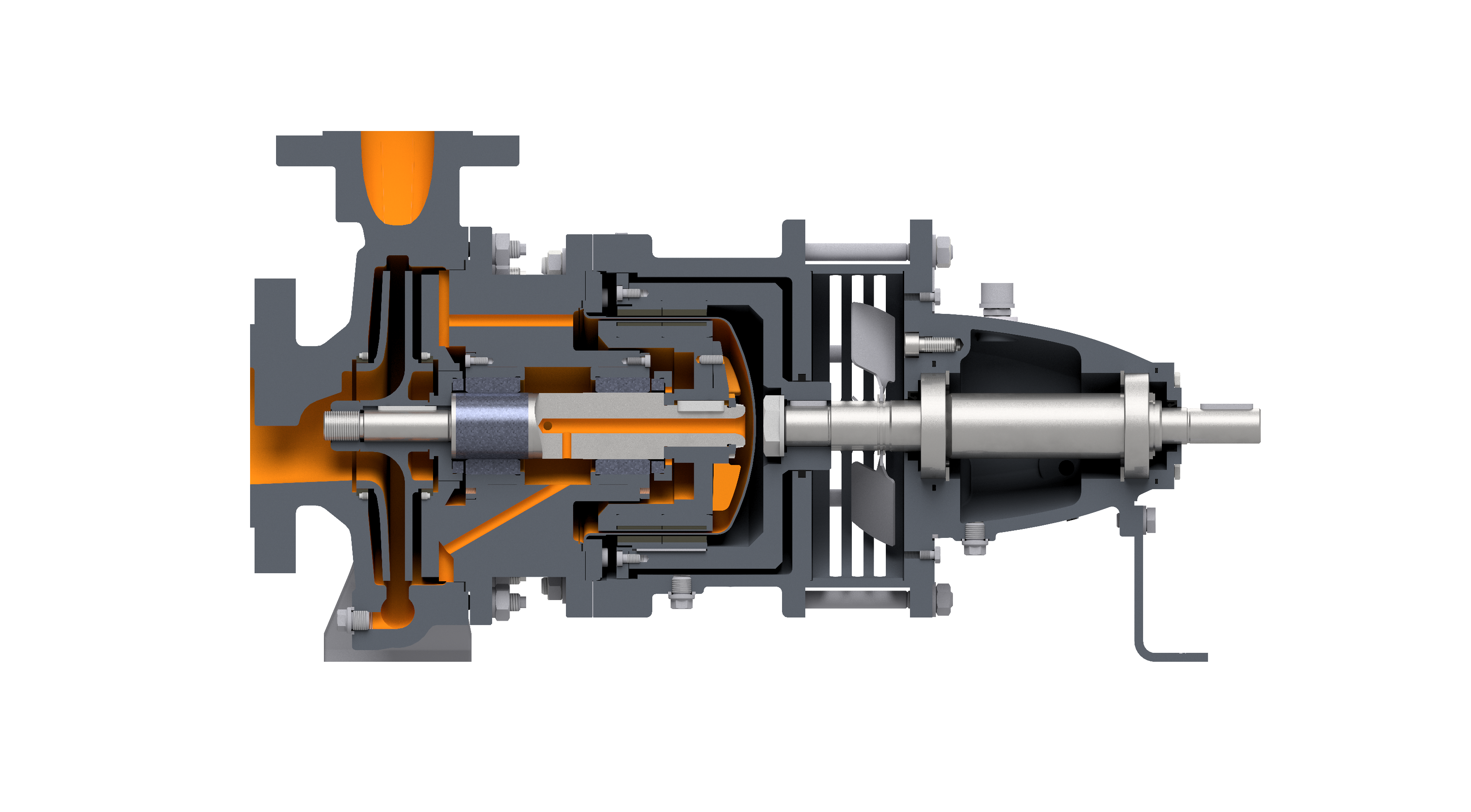

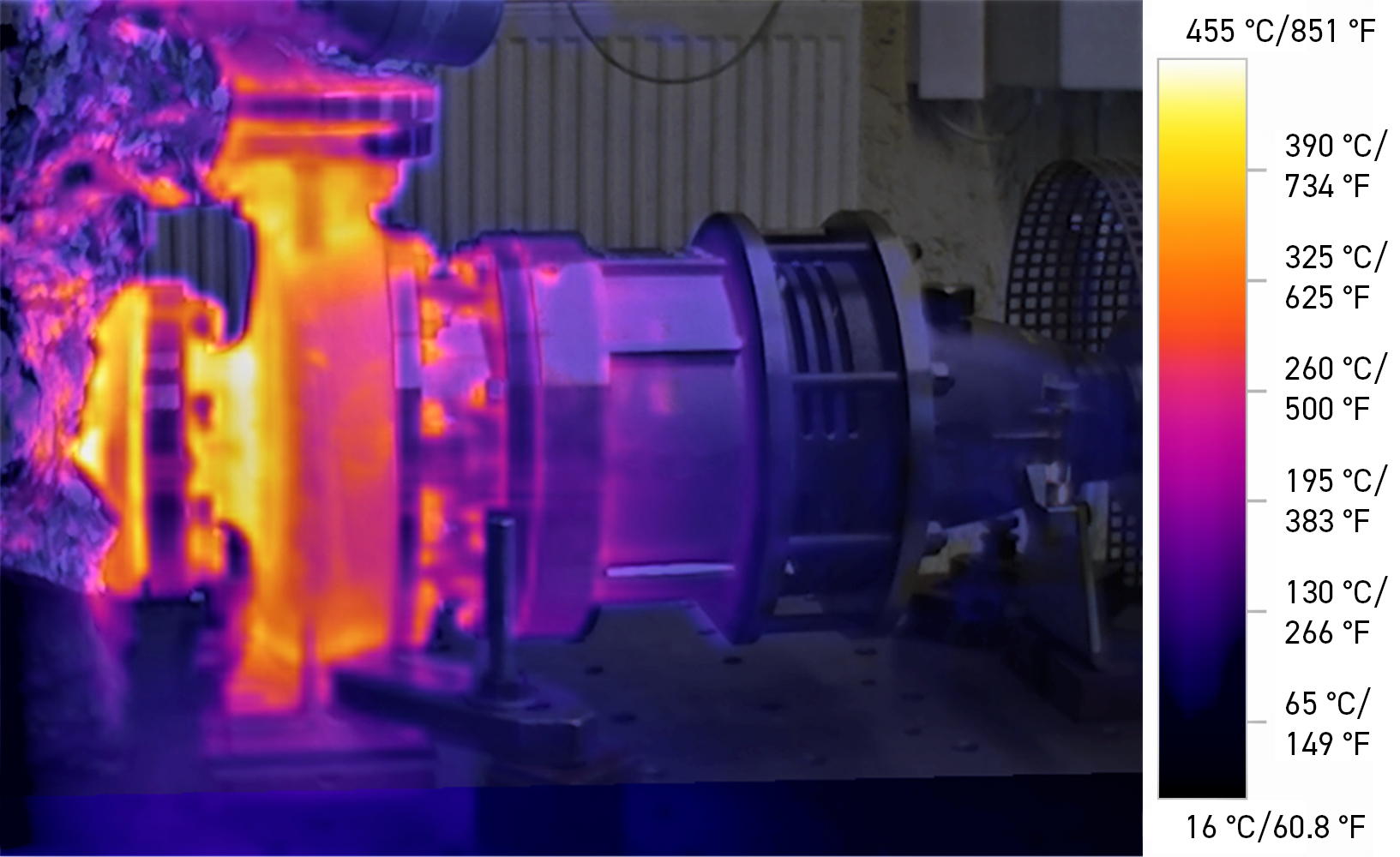

A new development from the manufacturer is a magnetic coupled and self-venting pump that has been specially developed for heat transfer applications. It was tested by the researchers of the German Aerospace Centre (DLR). It has the ability to handle temperatures of up to 500° C and pressures of 50 bar reliably in continuous operation without external cooling, and is therefore setting new standards in pump technology. This capability is based on the latest developments in magnet and materials technology, which were previously considered unattainable. Through the harmonic combination of efficiency and robustness, the fluid flow machine makes a decisive contribution to the further development of sustainable industrial processes and positions itself as an indispensable tool in demanding applications.

New silicone oils enable film temperatures of 460° C

Heat transfer oils enjoy great popularity in such applications - for very good reason: Their excellent ability to absorb heat with high efficiency makes them to a preferred choice in numerous industrial applications. In addition, they enable almost pressureless heat transfer over a wide temperature range, which makes them both versatile applicable and reliable. The series from the market leaders from Waldkraiburg, represents a new generation of heat transfer pumps that the manufacturer has developed particularly for use with all types of modern thermal oils. This magnetically driven centrifugal pump operates reliable and easily exceeds the high limits of use of conventional heat transfer pumps. A special feature is the ability for self-degassing as well as the waiving of any external cooling. This offers a pure plug-and-play solution that requires no additional installations and at the same time guarantees maximum safety against operating errors and cost-intensive machine downtimes.

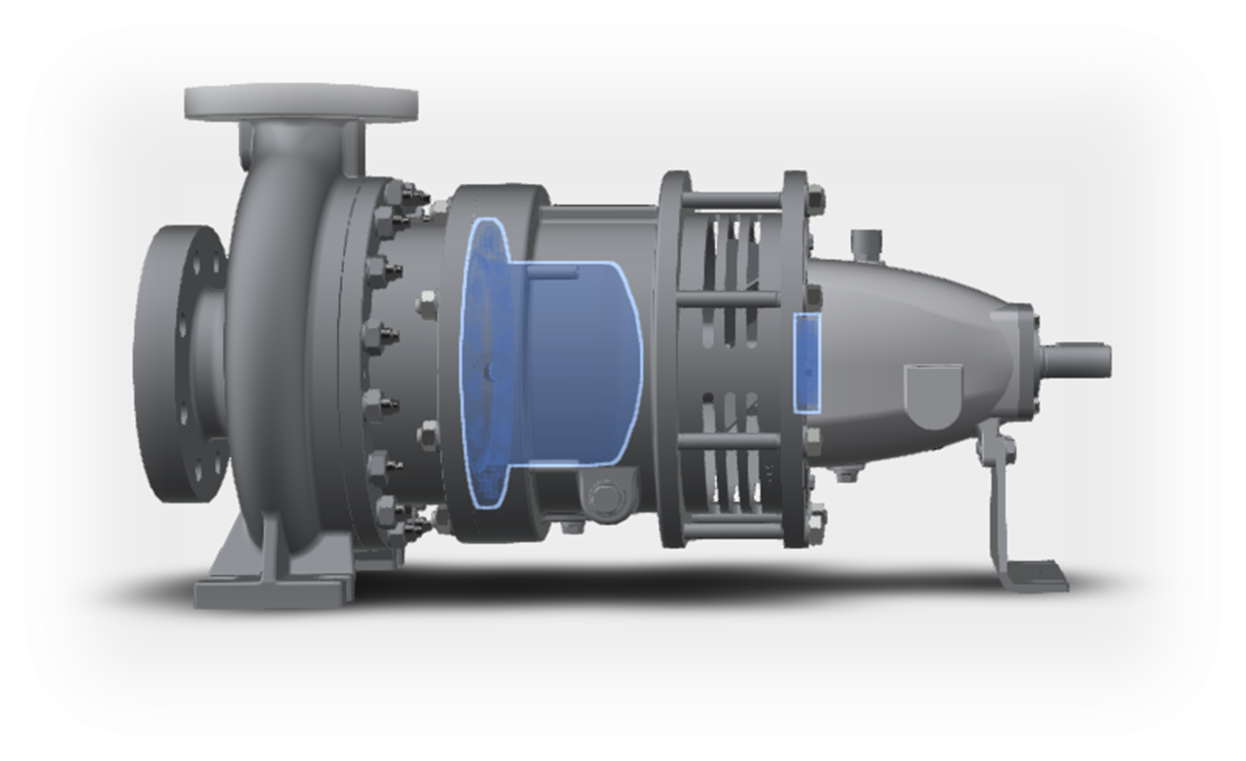

This image visualizes the distance from the contaiment shell to the bearings. source : Dickow Pumpen

The magnetically coupled pump handles medium temperatures of more than 400° C while the motor area is more than 330° C less warm. source: Dickow Pumpen

Increased operating safety

The design of the pump series also includes a hermetically sealed containment shell, which is located in a separate housing. In addition, a graphite safety packing provides a solid sealing to the atmosphere. If required, the pump can be equipped with a secondary mechanical seal and a leakage switch or other monitoring options, to reduce the leakage of the pumped liquid to an absolute minimum in the extremely unlikely case of a containment shell rupture. This not only guarantees the protection of human and environment, but also considerable increases the operating safety.

At very high temperatures or excess of age, heat transfer fluids tend to have poor lubricating properties – a real challenge for conventional magnetic drive pumps, which are dependent on sleeve bearings to fulfil their function. The thrust bearings are susceptible, as they quickly reach their limits under high loads. The new pump series takes this a step further. It automatically and completely compensates the axial thrust in the released performance curve range. The start-up rings therefore have additional backup for any unwanted operating conditions.

The operating temperature of antifriction bearings also has a significant influence on their operating life and capability. This is why the pump specialist has integrated a so-called fan flow deflector in the new series. The component between the magnetic coupling and the roller bearings acts as a highly effective thermal barrier. This effectively ensures that the storage temperature always remains significantly below the critical values - even during continuous operation under extreme conditions. A reduction of the bearing temperature has an extremely positive effect on the operating life and the so-called Mean Time Between Maintenance (MTBM).

Active Flow Management

In addition, the developers have designed the magnet chamber of the pump to be directly flushed. It is critical that undesirable byproducts such as low-boiling separations or any nitrogen solubility cannot accumulate in the pump body.

In general, conventional hydrocarbon-based heat transfer fluids tend to change their chemical configuration and therefore their properties in the course of time. This decomposition depends on temperature and time. In modern silicone-based heat transfer oils, the solubility of nitrogen varied depending on temperature and pressure. With increasing temperature, the solubility of nitrogen rises significantly compared to other chemical substances. To secure that no byproducts accumulate in the pump design, the Dickow magnet pump is equipped with an active flow management system. This system provides an effective internal flow, that dissipates any gases and therefore lifts the efficiency and long-life cycle of the pump to a new level and nips potential breakdowns in the bud. This approach does not only eliminate risks, but also optimizes the performance and long-life cycle of the pump.

Minimal maintenance requirements

The pump series represents high efficiency with minimal maintenance efforts. The only maintenance effort that is required, is an oil change of the pump drive every 20,000 operating hours. The internal pump parts are wear-free and require no additional service. This significantly reduces the total cost of ownership (TCO) and makes the pumps to the ideal solution for users, who are looking for a long life cycle and minimal downtime. The manufacturer thereby offers a solution to the challenges that are associated with conveying heat carriers in combination with thermal energy storages. Due to their hermetical density, high temperature and pressure resistance as well as their energy efficiency and ease of maintenance, these pumps are suitable for use in complex applications and contribute to a successful heat transition.