Dickow Pumpen is an essential project partner of the DLR project "SING" and thus an important factor in the hottest thermal oil plant in the world. In the new pump test stand built by Dickow especially for this purpose, heat transfer fluids are tested for their resistance at temperatures of up to 480 °C. The aim here is to reduce the electricity generation costs of solar thermal power plants (CSP)*.

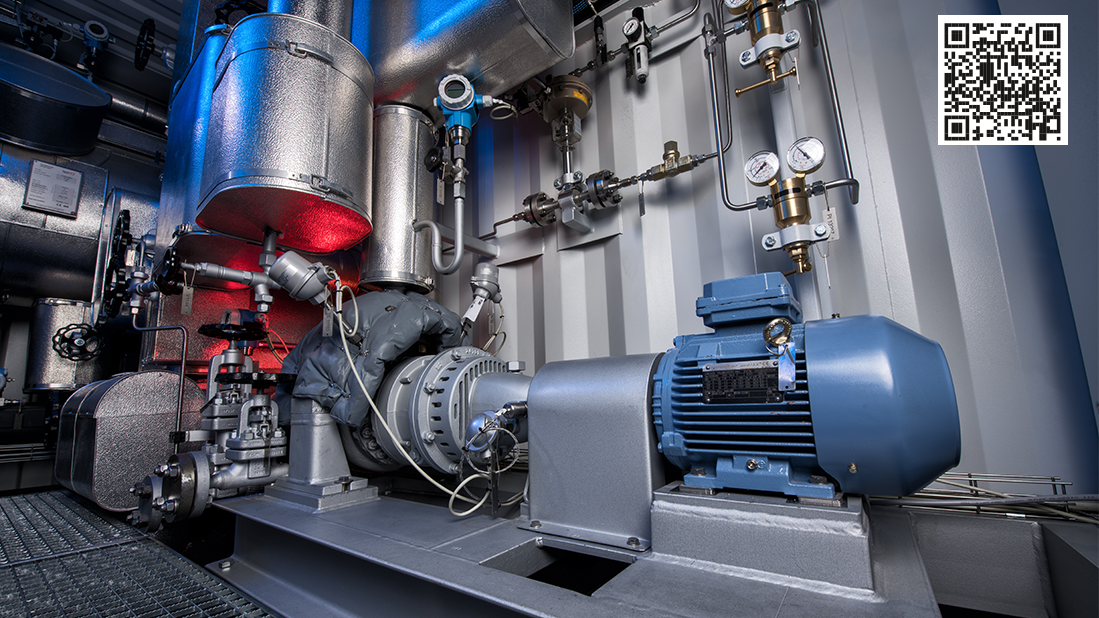

The "mobile heat transfer fluid and pump test stand" (MOPUW) from Dickow Pumpen presents innovative high technology, which until now seemed unattainable. The role of the main actor here is played by the Dickow pump series NMX. This heat transfer pump is the world's only magnetically coupled and self-venting pump that can operate continuously at up to 500 °C and 50 bar without external cooling. The latest magnet and material technologies as well as its simple operation open up application possibilities that are important for industrial energy supply. Especially solar thermal power plants, whose efficiency strongly depends on the temperature of the heat transfer medium, benefit from said properties. This assumption is being tested in the SING project.

Project SING as a system demonstration

In the SING project, the NMX heat transfer pump transfers a thermal oil at 450 °C for a period of about 4 months (3000 hours). Subsequently, the temperature is increased up to 480 °C for another 1000 hours. Without a pause for breath, this continuous cycle demonstrates both the stamina and performance of the pump and the temperature resistance of the oil. The complete system demonstration is officially tested by TÜV NORD and the first results are very promising.

While conventional heat transfer fluids age from a temperature of 400 °C, decompose and have to be replaced, the HELISOL®XLP silicone oil newly developed by Wacker, in addition to the NMX heat transfer pump, has proven its durability to date. As a result, plant runtimes could be significantly improved and efficiencies increased. This in turn will also help to use energy more efficiently in many other industrial sectors in the future.

*Solar thermal power plants (CSP)

In solar thermal power plants, the heat transfer fluid is heated by concentrated sunlight and fed into a heat storage tank or power plant block. Only there is the extracted thermal energy transferred via a heat exchanger to a steam cycle. The steam drives the turbine or generator, which in turn produces electricity. The higher the temperature of the heat transfer fluid, the more efficient the conversion of heat into electricity. In this way, both the proportion of electricity consumed from renewable energy sources is increased and the cost of the electricity generation itself is reduced.

Project partners and associated partners

Scientists of the Institute for Future Fuels operate the MOPUW test facility within the project SING (Silicone Fluid Next Generation). DLR is the project coordinator, and Dickow is the owner of the plant and integrated heat transfer pump NMX. Other project partners in the SING project are WACKER Chemie AG, flucon, TÜV NORD and Senior Flexonics. Associated partners are heat 11, Flagsol, Rioglass, RWE, STEAG as well as the Spanish research center CIEMAT subcontracted by DLR.

The project is funded by the German Federal Ministry of Economics and Climate Protection.